Emergency Shutoff Gas Valve

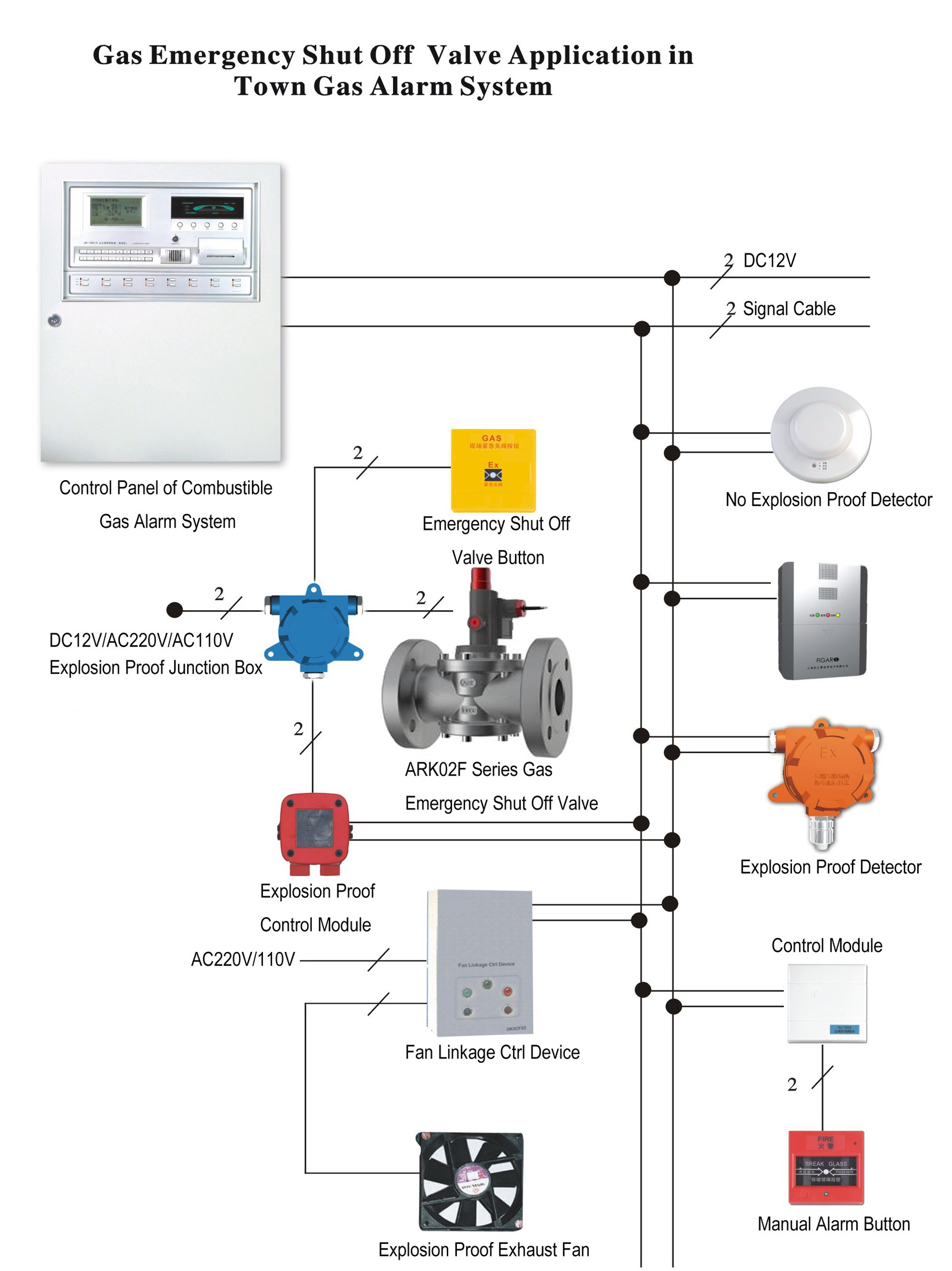

The Emergency Shutoff Gas Valve(including Residential class and Commercial class ) is a series of Industrial gas emergency shut off valves, specially designed as gas pipe breakers for emergency use. They can be connected with gas leak detection sensors, fire alarm circuits or other intelligent sensor modules so that on site or remote shutdown

on gas supply (manually or automatically) is possible, therefore ensuring safe gas usage.

The gas valve that is automatically(Pulse discharge,driving voltage:≤DC24V times:≤1S) closed by the safety control system or by an emergency device.

The valve can only be opened manually when environmental safety is confirmed.

ELECTRO-MAGNETIC EMERGENCY SHUT-OFF VALVE FOR GAS

1The Residential Class

1.1 The Residential Valve is a series of residential gas emergency shut off valves,specially designed as gas pipe breakers for emergency use. They can be connected with gas leak detection sensors, fire alarm circuits or other intelligent sensor modules so that on site or remote shutdown of the gas supply (manually or automatically) is possible, therefore ensuring safe gas usage.

1.2 The valve features an auto-close when a strong vibration (e.g. earthquake) is detected.

1.3 After auto-closing, manual operation is required to turn on the valve. This feature meets safety regulations in the event of an accident.

1.4 Characteristic:

1.5 Installation

2.The Commercial Class

![]()

2.1The Commercial Valve is a series of Industrial gas emergency shut off valves, specially designed as gas pipe breakers for emergency use. They can be connected with gas leak detection sensors, fire alarm circuits or other intelligent sensor modules so that on site or remote shutdown on gas supply (manually or automatically) is possible, therefore ensuring safe gas usage.

2.2The valve features an auto-close when strong vibration or earthquake is detected.

2.3After closure, manual operation is required to turn on the valve. This feature meets safety regulations in the event of an accident.

2.4.1The valve is designed with double structure of mechanical lock and permanent magnet lock.

2.4.2 When the valve is in open state, the spring force is overcome by mechanical lock structure, and the spring is locked in compressed state. The trigger structure of mechanical lock is fixed in open position by permanent magnet lock structure.

2.4.3 When the valve receives the shut-off signal, the discharge module will output pulse current to the electromagnetic coil in permanent magnet lock structure. The instantaneous magnetic force generated by the impulse current will unlock the permanent magnet lock structure, and the trigger structure will run to the closed position.

2.4.4 When the trigger structure reaches the closed position, the mechanical lock will be unlocked, and the valve will be closed by the spring force.

Item | Parameter |

Sealing material | NBR/FKM |

Valve body material | Casting aluminium alloy(ZL101A)、WCB |

Valve closing mode | 1、Passive manual closing valve;2、DC12V pulse drive(times≤1S) |

Status | The gas valve that is automatically(Leakage Detector Pulse discharge, time≤1S) closed by the safety control system or by an emergency device. The valve can only be opened manually when environmental safety is confirmed. |

Action reliability | More than 3000 times |

10years | |

Standard | QB/0001-2018、GB3836.1-2010、GB3836.9-2014、CJ/T394-2018 |

Maximum working pressure | DN≤20mm:0.02MPa/0.10MPa/0.20MPa 25mm≤DN≤400mm:0.1MPa/0.4MPa/0.6MPa |

Ambient temperature | -10℃~+50℃ |

Place of use | Zone 1, zone 2 in explosive gas environment |

Explosion proof mark | Ex mbⅡB T6 Gb |

Levels of protection | IP54/IP65(Require cover), Steel pipe or casing connection at cable-exit position to form a sealed environment |

Attended mode | Thread/Flange connection (PN16) |

Gas source type | Natural gas, liquefied petroleum gas and artificial gas |

Cable length | 0.45M/Customer customization |

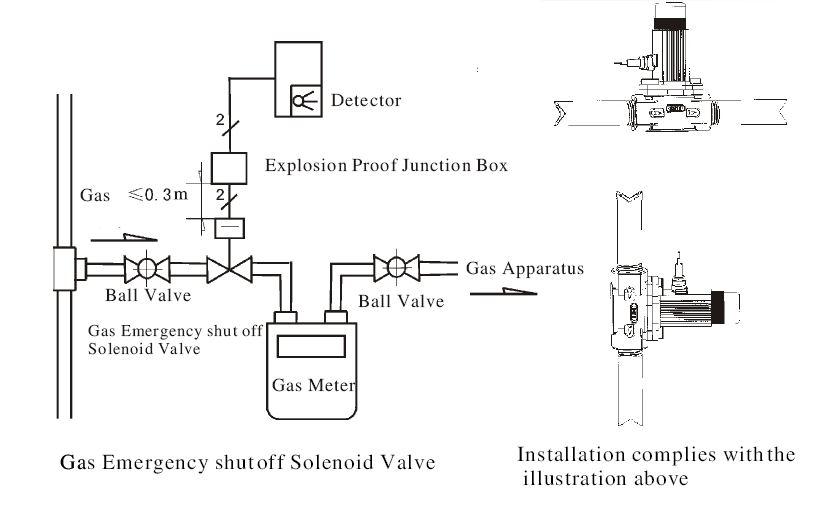

2.5 Installation